What does it do?

The primary purpose of stemming material is to confine the energy generated during explosive detonation. This confinement allows the energy to effectively fracture the rock mass surrounding the stemming zone at the top of the borehole, ensuring optimal fragmentation and minimizing the risk of flyrock and air overpressure from venting gases.

Where is it used?

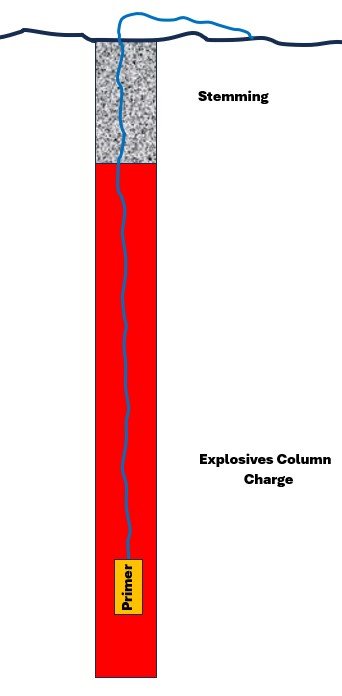

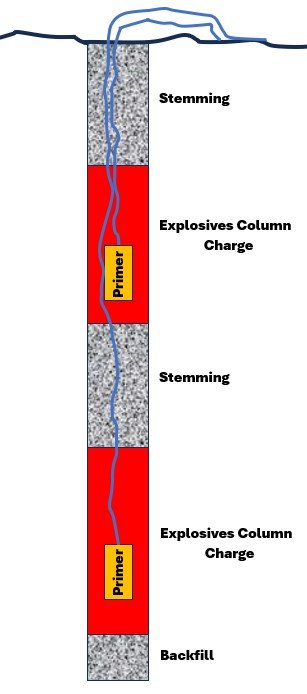

Stemming is typically positioned above the explosive column charge and extends to the top of the borehole.

It can also serve to separate multiple explosive decks within a single borehole or be used for backfilling in cases where boreholes have been drilled deeper than planned.

What is it made from?

Inert materials such as crushed rock, drill cuttings, sand, clay, and water are commonly utilized for stemming. Among these, crushed rock is the most popular due to its excellent interlocking properties, effectiveness in wet holes, wide availability, and cost efficiency in bulk. Additionally, specialized expanding and foam stemming products are also available to enhance performance in specific applications.

crushed rock has great interlocking properties and compatibility with wet holes

Stemming Length and Particle Size

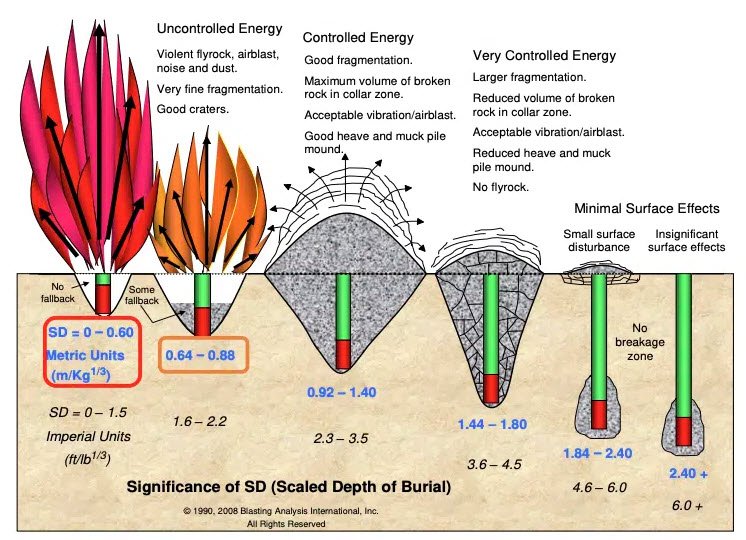

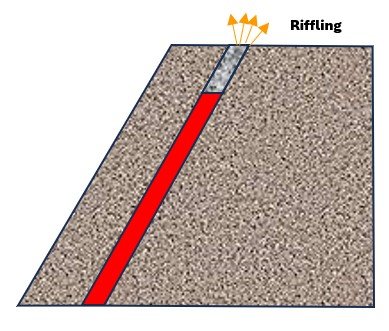

Correct stemming length and particle size are critical factors in controlling fragmentation, flyrock, and airblast in blasting operations. Two key mechanisms associated with airblast and flyrock that are directly related to stemming include:

Riffling: Occurs when the stemming length is insufficient, the chosen stemming material is unsuitable, the particle size is incorrect for the hole diameter, or the quality of the stemming material is compromised due to contamination or excessive fines. Proper selection and management of stemming materials are essential to prevent riffling and ensure effective blast performance.

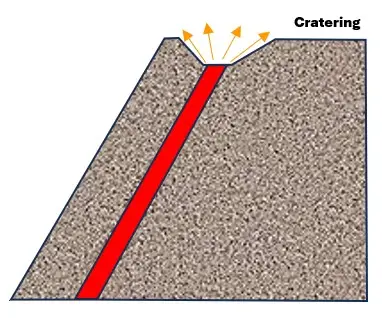

Cratering: Cratering occurs when explosive gases vent in the surrounding area of the blast hole. This can happen in weak materials caused by factors such as faulting, dykes, or clay bands.

Excessive preconditioning from previous blasts is another contributing factor, often resulting from over-drilling or improper backfilling of holes.

Additionally, inadequate drill bench preparation, where the bench has not been excavated back to solid ground, can further exacerbate cratering issues. Proper management of these factors is essential to minimize the risk of cratering and ensure effective blasting operations.

Calculating Stemming Length and Particle Size

The following are rules of thumb for calculating stemming length and particle size. Please note that these guidelines serve as starting points only and should be adapted based on specific site conditions and operational requirements.

Particle Size = 0.1 x hole diameter.

Stemming Length = 20 – 30 x hole diameter.

Example:

Hole Diameter: 229 mm

Particle Size: 229 x 0.1 = 22.9 mm

Stemming Length

Min: 229 x 20 = 4.58 m

Max: 229 x 30 = 6.87 m

Disclaimer: Caution should be exercised, and blast exclusion zones should be set with sufficient built in safety factors. Results should be monitored and adjusted for site specific conditions.

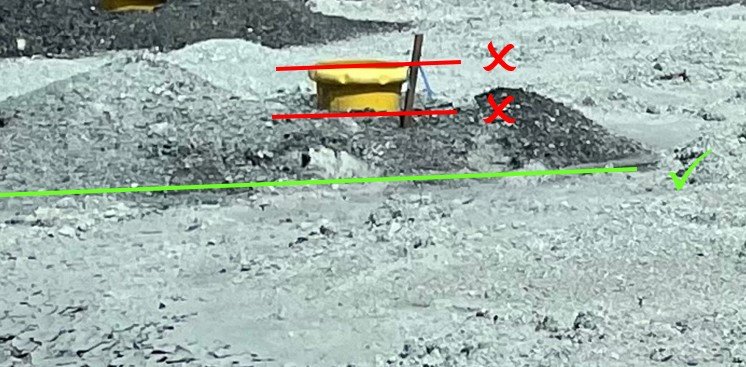

Measuring Stemming Length

Stemming length should be measured from the surface of the hole, referencing the level of the surrounding drill bench, rather than from the top of the drill cuttings or any hole saver used. It’s essential to ensure that blast crews are properly trained in measurement techniques to maintain accuracy and consistency.

Application Considerations

Risk Assessment: Evaluate risks related to proximity to properties, plants, or infrastructure, including potential flyrock, vibration, and air overpressure.

Type of Blast: Identify the specific type of blast (e.g., production, pre-split) to determine appropriate stemming strategies.

Diameter of Blastholes: Take into account the diameter of the blastholes when selecting stemming material and determining length.

Depth of Preconditioning: Check for preconditioning effects from previous blasts above to inform stemming choices and adjustments.

Stemming Quality: Ensure consistent quality of stemming material, checking for excessive fines and ensuring it meets required specifications.

Contamination: Consider the effects of muddy water and explosive product reactions, which may lead to foaming or other complications.

Measurement of Stem Height: Use consistent measurement techniques between different personnel to ensure accurate measurement of stemming height.

Borehole Conditions: Evaluate borehole conditions, including the presence of water, clay bands, and fractures, which can influence stemming effectiveness.

Wet Holes: Be mindful of potential issues such as blockage or bridging in wet holes.

Blasthole Liners: Assess the use of blasthole liners and their impact on the ability to stem holes.

Stemming Cost: Consider the costs associated with different stemming products for backfilling and intermediate stem decks.

Conclusion

At first glance, stemming may seem like a very minor component of the blasting operation. However, it plays a crucial role which can directly impact the efficiency of mining equipment, compliance with environmental regulations, the safety of personnel, equipment, and infrastructure, as well as a company’s license to operate, and ultimately, its bottom line.

Understanding the implications of stemming is essential. Train your personnel, implement best practices, monitor results, and make necessary adjustments. By doing so, you position yourself and your site to achieve safe and effective blasting outcomes, maximizing both operational efficiency and safety.